Production

All production techniques at our disposal

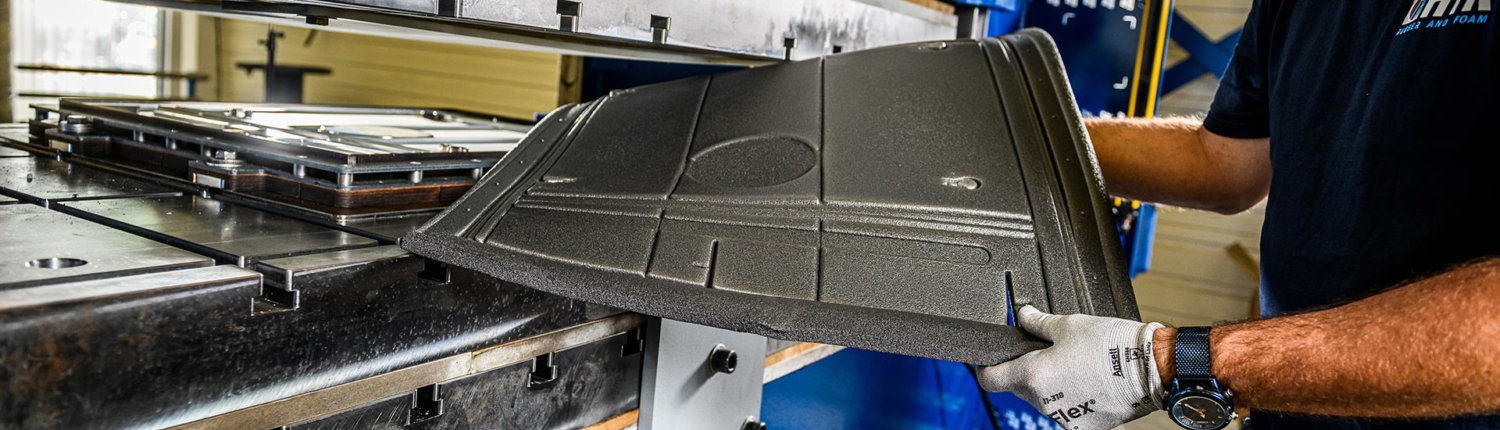

We use all possible production techniques for rubber and foam.

Extrusion, moulding (via injection moulding, transfer moulding, compression moulding or LSR), thermoforming, vacuum forming, punching, cutting, spooling, kiss cutting and laminating are all part of our everyday work. We also provide moulded hoses and make your rubber and foam products self-adhesive.

Our advisers will be happy to inform you about the possibilities.

Contact us to find out what HTR can do for you.

Global production

In 2011, we established a branch in India. Here, among other things, labour-intensive production of rubber products takes place.

From our different locations, we can quickly serve you anywhere in the world. For service, support and logistics, our offices in the Netherlands and Germany are of course your trusted point of contact.

Quality at the right price

Thanks to international production, we can deliver high-quality rubber products at highly competitive prices. HTR thereby ensures cost savings through the most optimal design, the best-fitting technical specifications, the right production technique, the shortest assembly time and the most optimised packaging – plus highly cost-efficient production.